Unlocking Innovation with High-Throughput Experimentation (HTE)

Imagine accelerating your entire R&D pipeline—what used to take months now happens in days. That’s the power of High-Throughput Experimentation (HTE).

HTE is transforming scientific research by enabling the parallel execution of hundreds of experiments, dramatically speeding up discovery and development. This approach is already making a significant impact across industries such as pharmaceuticals, agrochemicals, fragrances, energy & sustainability, and material science.

By combining automation and miniaturization, HTE allows researchers to conduct hundreds of experiments in a fraction of the time required by traditional methods. When integrated with data science and machine learning, HTE becomes a powerful tool for systematically exploring chemical space and driving innovation through data-driven decision-making.

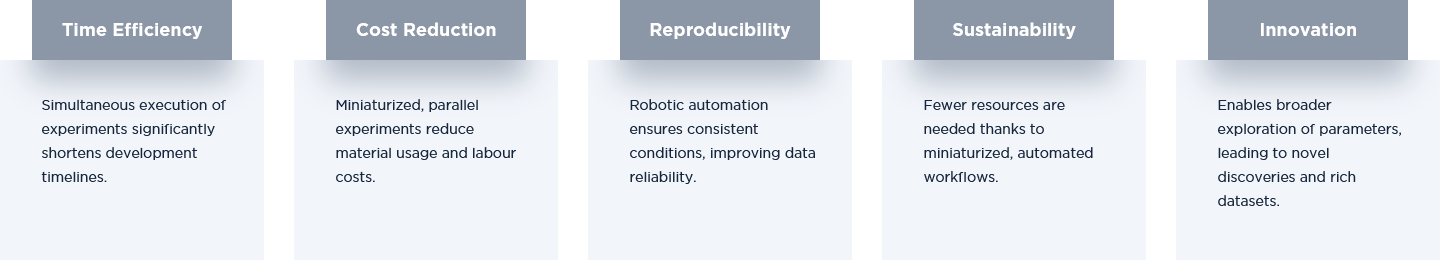

Key Benefits of HTE

Application Areas

High-Throughput Experimentation (HTE) is a versatile platform that supports the entire pharmaceutical development lifecycle. From early-stage drug discovery to process optimization and regulatory filing, HTE enables rapid, data-rich experimentation that drives informed decision-making at every step.

Services and Offerings

HTE services can be offered as part of a fully integrated process chemistry solution or as standalone services, depending on project needs. These services include:

How Do We Differentiate?

We differentiate ourselves through a unique combination of advanced technology, data-driven methodologies, and deep scientific expertise. Our state-of-the-art robotic laboratory operates 24/7 with minimal human intervention, ensuring maximum productivity, consistency, and reproducibility.

This high level of automation enables rapid, data-rich experimentation, delivering deeper insights and faster decision-making. We further enhance our capabilities by integrating machine learning into expansive datasets, uncovering patterns and predictive insights that traditional methods often miss.

At the core of our success is a team of scientists with decades of experience in HTE, synthesis, process chemistry, and catalysis—bringing high-quality outcomes and innovative solutions to every project.

By merging cutting-edge tools with expert knowledge, we redefine what’s possible in High-Throughput Experimentation and drive innovation across industries.

Ready to transform your R&D strategy?

Let’s talk about how HTE can accelerate your innovation.