Quality Control

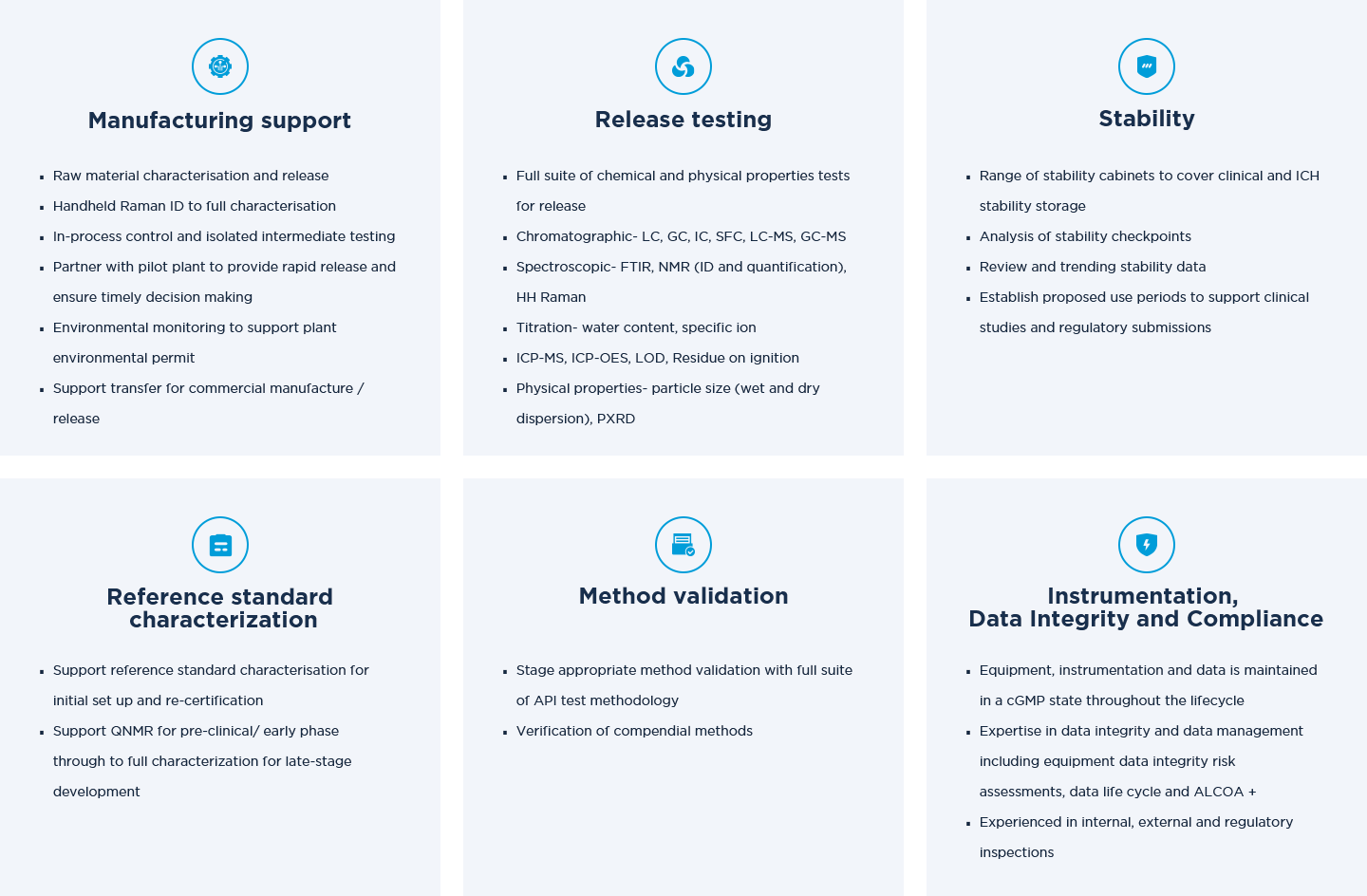

At Asymchem, Quality Control goes far beyond testing against specifications; it is at the core of everything we do. We are committed to delivering exceptional science and ensuring compliance throughout the entire development lifecycle.

Our team, with an average of over 20 years of experience in the pharmaceutical and CDMO industries, brings a wealth of expertise across R&D and commercial. Our scientists have led projects at every stage of development and have implemented continuous improvement initiatives that deliver value to a wide range of stakeholders.

The Asymchem QC culture is built on collaboration and partnership throughout the method development lifecycle. With years of proven excellence in troubleshooting and providing critical method feedback, we ensure robustness at every phase—from early development through to commercial production.